Dust Control and Air Filtration: Protecting Your Heavy Equipment Engines in Dry Lexington Summers

The picturesque scenery and arid climate of Lexington, Oregon make it a beautiful place to live and work, but for heavy equipment operators and construction professionals, the region’s dusty summer months pose a serious threat to machinery. Dry, dusty environments are a nightmare for engines and mechanical systems, especially in rugged industries such as construction, mining, and agriculture. With the right dust control and air filtration strategies, however, you can dramatically extend the life of your equipment and protect your investments.

Dust control and air filtration protecting heavy equipment engines isn’t just about extending engine life—it’s about maintaining peak performance, reducing downtime, and cutting operational costs. Lexington summers, often hot and dry, create perfect storm conditions for airborne particles to infiltrate and damage engine components. Fortunately, through a combination of proactive maintenance and smart filtration choices, businesses can stay ahead of dust-related engine issues and keep their heavy equipment in prime condition year-round.

Dust and Its Impact on Heavy Equipment Engines

Dust may seem like a harmless annoyance, but it is one of the most pervasive and damaging elements for any mechanical system. In Lexington, OR, summer brings relentless winds and dry spells that send clouds of fine dust into the air, often invisible to the naked eye. This fine particulate matter has a remarkable ability to infiltrate engine compartments, lodge into filters, and abrade internal components.

Heavy equipment engines are particularly vulnerable because they rely on precise tolerances and clean air intake systems to function efficiently. When dust enters an engine’s air intake, it accelerates wear on components like cylinders, pistons, valves, and bearings. Over time, this contamination leads to increased oil consumption, decreased compression, loss of power, and ultimately, engine failure.

The risks are amplified during Lexington summers, when extended hours of operation and dry conditions push engines to their limits. Whether you’re operating excavators, loaders, tractors, or bulldozers, without rigorous air filtration and dust control protocols, you’re effectively reducing the service life of your equipment every time you start the engine.

Why Air Filtration is Crucial in Lexington’s Dusty Climate

Air filtration in heavy equipment serves as the first line of defense against dust intrusion. A high-quality air filter traps airborne contaminants before they enter the engine, maintaining a clean and stable airflow essential for combustion. The key is using filters specifically designed to handle high-dust environments like those found during Lexington summers.

Selecting the best air filters for heavy equipment in dusty conditions, Oregon operators must look for models rated for extreme environments. These often feature multi-stage filtration systems that include a primary and secondary filter. The primary filter captures large particles, while the secondary ensures any remaining microscopic debris is caught before reaching the engine.

Regular inspection and replacement of air filters are just as important as the filters themselves. Even the best filter becomes ineffective when clogged. Operators should adopt a strict maintenance schedule during the peak summer months, ensuring filters are checked daily and replaced as needed to prevent airflow restriction and engine strain.

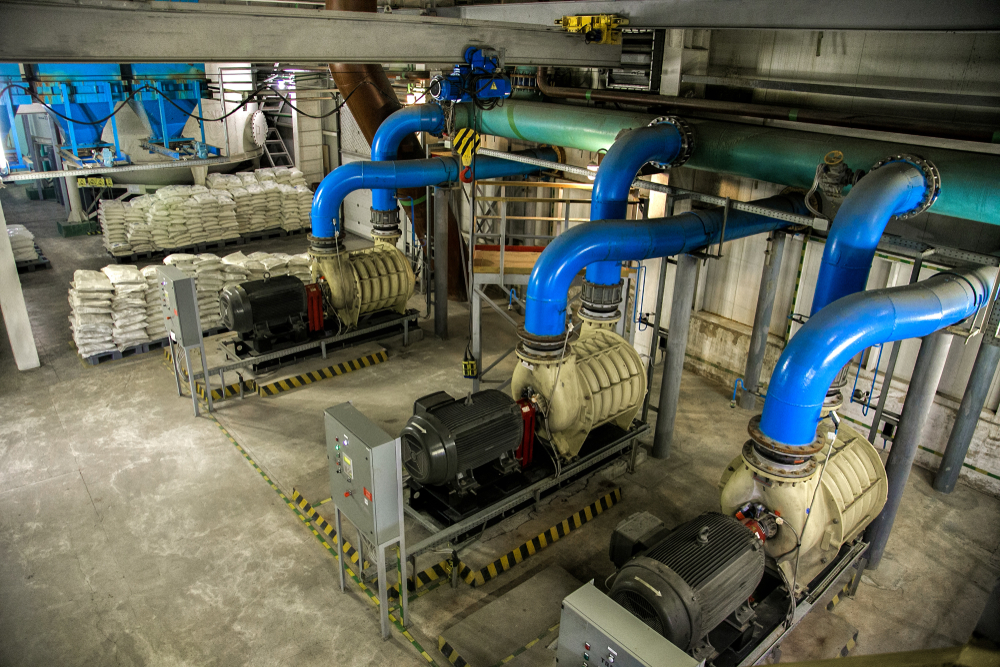

Beyond traditional filters, pre-cleaners and centrifugal air filtration systems can be added to heavy equipment to enhance dust separation. These systems use inertial forces to spin out dust before it even reaches the filter element, dramatically extending filter life and reducing maintenance demands.

Dust Control Strategies on Job Sites: Minimizing Exposure

In addition to optimizing air filtration, dust control on the job site plays a pivotal role in protecting heavy equipment. Effective dust control reduces the volume of airborne particles, thereby lowering the amount of dust that filters need to handle and minimizing exposure for both equipment and operators.

Water trucks, misters, and chemical suppressants are commonly used to keep dust levels down on active job sites. In Lexington, where water resources may be limited in summer, targeted application of dust suppressants to high-traffic areas can be especially effective. Graveling access roads, reducing vehicle speeds, and rotating site traffic patterns can also help reduce dust generation.

Another key aspect of dust control involves careful planning and preparation. Clearing and grading activities should be scheduled during cooler parts of the day when winds are typically lower. Additionally, barriers such as fencing or vegetation windbreaks can shield sites from prevailing winds, further reducing dust spread.

Employing a site-specific dust control plan not only improves working conditions but also preserves your heavy equipment’s performance. By attacking the problem at its source, you significantly cut down on the dust load your filtration systems need to handle, resulting in less wear and longer equipment life.

Best Practices: How to Prevent Dust Damage to Heavy Equipment Engines in Lexington, OR

Preventive maintenance and proactive monitoring are at the heart of effective dust control and air filtration strategies. To truly understand how to prevent dust damage to heavy equipment engines, Lexington, OR operators must view maintenance as a continuous cycle rather than a reactive response.

Daily pre-operation checks are non-negotiable in dusty environments. These checks should include visual inspections of air filters, seals, engine compartments, and intake ducts. A simple tear in an intake hose or a loose seal can allow dust to bypass filtration systems entirely, rendering even the best filters useless.

Oil analysis is another essential practice. By monitoring the oil for signs of silica and other abrasive contaminants, technicians can detect early signs of dust ingress and address the issue before engine damage becomes irreversible. Keeping detailed maintenance logs helps identify patterns and problem areas, allowing teams to make data-driven decisions.

Cabin air filters and HVAC systems should not be neglected either. Dust infiltration into operator cabins not only affects comfort but can damage sensitive electronics and reduce visibility if left unchecked. Ensuring sealed cabins and properly functioning ventilation systems adds another layer of protection, both for machines and operators.

When selecting equipment, look for models with enhanced sealing and filtration options. Modern machines often come with upgraded dust protection packages that include reinforced engine enclosures, pre-cleaners, and enhanced air intake routing designed to resist dust penetration.

Long-Term Value: Investing in Equipment Protection and Operational Efficiency

While some may view air filters and dust suppression efforts as additional expenses, the long-term savings from reduced downtime, lower repair costs, and extended engine life far outweigh the initial investment. Dust control and air filtration protecting heavy equipment engines is not a luxury—it is an operational necessity in environments like Lexington.

Operators who prioritize dust control strategies and invest in the best air filters for heavy equipment in dusty conditions, Oregon’s challenging climate, reap the rewards in equipment longevity and reliability. More uptime means more productivity, fewer emergency repairs, and increased project efficiency.

In a competitive industry where every dollar counts, protecting your assets should be a top priority. Smart filtration and dust control practices are proven, cost-effective methods to ensure your heavy machinery continues to perform at its best—even through the driest and dustiest Lexington summers.

Conclusion

Ultimately, the health of your heavy equipment reflects the health of your operations. By understanding the dangers of dust, investing in proper air filtration systems, implementing site-wide dust control strategies, and embracing preventive maintenance, you set the foundation for long-term success. Lexington may bring its share of summer challenges, but with the right preparation, your engines will remain strong, clean, and ready to tackle whatever comes next.