The Importance of Regular Brake System Inspections and Maintenance for Heavy Trucks

When it comes to the operation of heavy trucks, safety is always a top priority. Among the most vital safety components in any commercial vehicle are the brakes. Without a fully functional brake system, a truck becomes a significant risk to the driver, other road users, and the cargo it is transporting. Regular brake system inspections and maintenance are essential for ensuring that heavy truck brakes remain in optimal working condition, contributing to the overall safety of the vehicle and preventing costly repairs down the line. In this blog, we’ll explore why brake maintenance is so important for heavy trucks, how often brake inspections should be performed, and the signs of brake problems that truck drivers and fleet managers should watch for.

Why Heavy Truck Brake Maintenance is Crucial

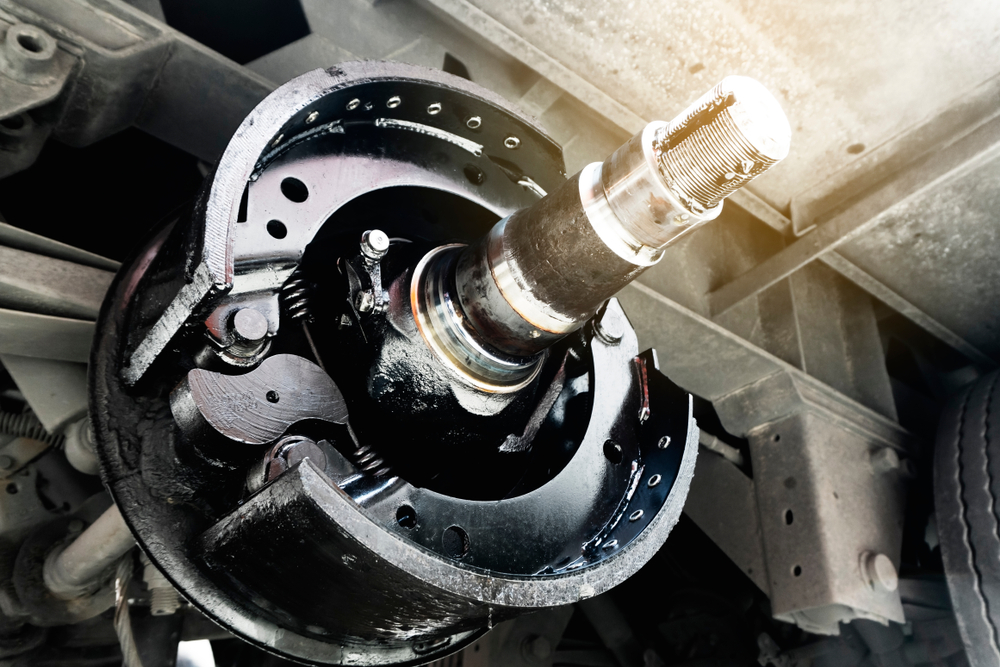

The importance of heavy truck brake inspections cannot be overstated. Heavy trucks are constantly on the road, sometimes covering thousands of miles each week. The sheer weight of these vehicles, combined with the added stress of frequent stops, high-speed driving, and extreme weather conditions, puts significant pressure on the brake system. Over time, this stress can cause wear and tear on key components such as brake pads, rotors, drums, and hydraulic systems, all of which are vital for the truck’s braking performance.

Without regular truck brake maintenance, these components can deteriorate to the point where the vehicle’s braking ability becomes compromised. In worst-case scenarios, this can lead to brake failure, causing accidents or severe damage to the truck. For fleet operators, an out-of-service truck due to brake issues can result in significant downtime and lost revenue. Furthermore, serious accidents caused by faulty brakes can lead to costly liability claims, lawsuits, and insurance hikes. Therefore, maintaining the brake system is not just a safety issue—it’s also a financial and operational concern for any business that relies on commercial trucks.

The Role of Regular Brake Inspections

One of the most effective ways to maintain the braking system on heavy trucks is through regular brake inspections. Brake inspection trucks should be scheduled periodically to ensure that each truck’s brake components are functioning as expected. Typically, commercial trucks should undergo brake inspections every 10,000 to 15,000 miles or after extended periods of heavy usage. However, this can vary depending on the specific use case of the truck, such as whether it operates primarily in urban areas or on highways. Urban driving, with frequent stops and starts, places more strain on the brakes and may require more frequent inspections.

During an inspection, a technician will check various components of the braking system, including the brake pads, rotors, hydraulic fluids, brake lines, and other related systems. They will also assess the performance of the air brake system, which is commonly used in heavy trucks. Air brakes are critical for providing the necessary stopping power, and their performance should be regularly tested to ensure proper functionality.

Failing to perform regular brake inspections can allow small issues to go unnoticed, leading to more significant problems down the road. For example, a minor leak in a brake line or a slight imbalance in the air brake system might not be immediately apparent to the driver. However, over time, these issues can worsen, eventually leading to brake failure. Preventing such occurrences through regular inspections is key to maintaining safety and operational efficiency.

The Dangers of Neglecting Brake Maintenance

Neglecting brake maintenance can have serious consequences for truck drivers and their employers. The most obvious risk is the increased likelihood of accidents caused by brake failure. Heavy trucks require a significant amount of stopping power, and without properly maintained brakes, stopping distances can increase dramatically, especially when carrying a full load. This delay can be the difference between avoiding a collision and causing a catastrophic accident.

Another danger of neglected brake maintenance is the potential for costly repairs. Over time, worn-out brake pads and rotors can lead to deeper damage within the brake system. For example, if brake pads are allowed to wear down completely, the metal backing plate can grind into the rotor, causing grooves and scoring that may require costly rotor replacement. Similarly, if air brake systems are not regularly serviced, issues such as contaminated air or leaks can compromise their effectiveness, leading to more expensive repairs and replacements.

For fleet managers, the costs associated with neglected brake maintenance extend beyond repair bills. A truck that’s out of service due to brake failure can disrupt schedules, leading to delayed deliveries, loss of revenue, and frustrated customers. In the long run, this can erode the reputation of the trucking company, causing clients to seek out competitors who offer more reliable services. Therefore, investing in regular brake maintenance for commercial trucks is not only a safety measure but a way to safeguard the company’s profitability and reputation.

Identifying Signs of Heavy Truck Brake Problems

Being able to identify the early signs of heavy truck brake problems can help prevent catastrophic failure. It is essential for both drivers and fleet managers to be aware of common signs that indicate the brakes may not be functioning optimally. One of the most obvious signs of brake trouble is a noise, such as squealing, grinding, or thumping sounds, when the brakes are applied. This often indicates that the brake pads are worn out or that debris has become lodged in the brake components.

Another red flag is if the truck pulls to one side when braking. This could indicate that the brake pads are unevenly worn, or there may be an issue with the brake fluid or the air brake system. Drivers should also be on the lookout for any vibrations in the brake pedal when pressure is applied. This can be caused by warped rotors, which occur when the braking system is subjected to excessive heat, often due to prolonged or aggressive braking.

Additionally, if the truck’s stopping distance seems longer than usual or the brakes feel less responsive, this may be a sign of brake fluid leaks or air pressure issues. Leaking brake fluid can cause the system to lose hydraulic pressure, reducing braking power. If the brake warning light appears on the dashboard, it’s crucial to inspect the system immediately to determine whether the issue lies with the fluid level, pressure, or other components.

Lastly, if there is a noticeable decrease in braking power when descending steep grades or driving in challenging conditions, it may indicate an issue with the brake system’s capacity to dissipate heat. This could be a sign of overheated brakes, worn-out brake linings, or issues with the air brake system.

The Bottom Line: Safety and Efficiency Go Hand-in-Hand

The safety of truck drivers and the general public depends on the reliability and functionality of the brake system in heavy trucks. Regular brake maintenance and inspections are vital in preventing accidents, ensuring vehicle uptime, and avoiding costly repairs. For fleet operators, it’s essential to establish a proactive maintenance schedule that includes regular brake inspections to ensure that the truck brake system is always in optimal working condition. This not only enhances truck safety but also contributes to the smooth operation and financial success of the business.

Recognizing the signs of brake problems and addressing them promptly is key to preventing more severe issues down the road. Whether you are a truck driver or a fleet manager, maintaining a sharp focus on brake performance and safety should always be a priority. After all, the safety of the driver, cargo, and everyone else on the road depends on the reliability of a heavy truck’s brake system.